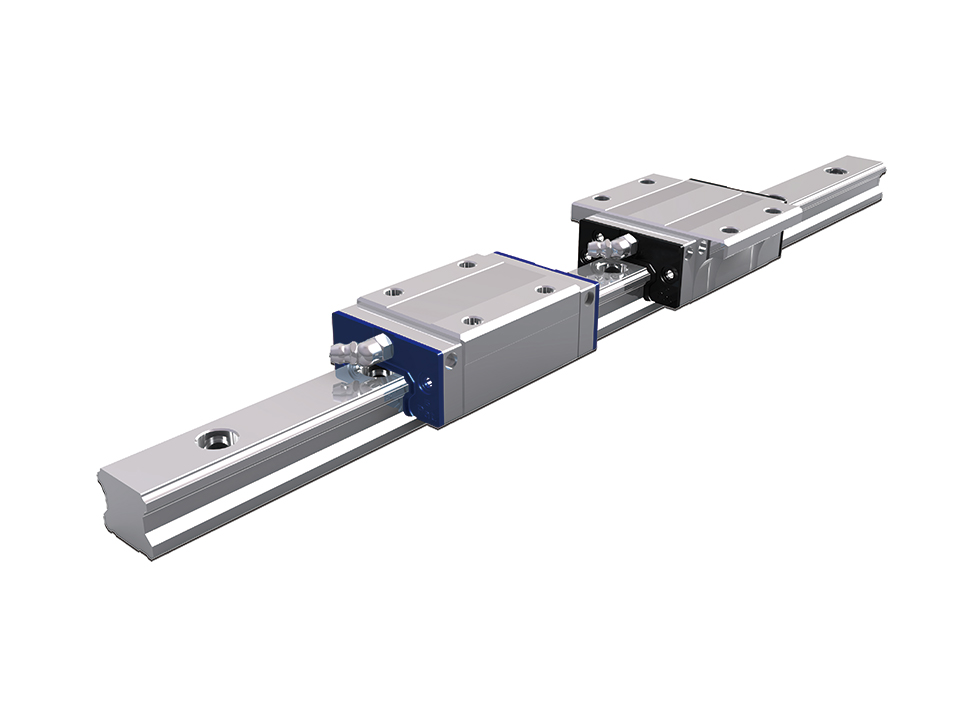

How Often Do You Need to Lubricate Your Linear Guides?

NTN Linear guides of all series are provided with lubrication at the time of delivery. The guides should be relubricated after installation with the grease amount from Table 4.7 of the Linear Guide Catalog. This is done in two to three steps with intermediate movement over a longer stroke for optimal grease distribution in the system. The guides also require lubrication before a prolonged shutdown and before re-operation. Please note – compatibility of the lubricants must be checked when the lubricant type is not the same type as originally supplied by NTN.

Influence factors

The relubrication intervals are affected by several factors. Load and contamination usually have the strongest effect. Accurate relubrication intervals for a specific system can only be determined after the actual operating conditions have been assessed for a sufficiently long period.

Lubrication interval for conventional linear guides and grease lubrication

The default value for relubrication with grease for conventional guide systems (LGBX series) under normal operating conditions is every six months or after 100 km travel distance. This value can be adjusted upwards or downwards under special environmental conditions. The lubrication interval should not be longer than two years or 500 km travel distance, even under optimal environmental conditions, without contamination and low load. The amounts specified in Table 4.8 of the Linear Guide Catalog should be used for relubrication.

Lubrication interval for linear guides with ball chain and grease lubrication

These values significantly improve for the same conditions when guiding systems with integrated ball chain (LGBG, LGMC series) are used. The default value for NTN linear guides with ball chains under normal operating conditions is lubrication once per year or after 500 km of travel distance. This value may have to be adjusted upwards or downwards under special environmental conditions. A travel performance of several thousand kilometers between maintenance steps is possible when the environmental conditions are good and the load is low. The maximum usable life of the lubricant must be considered when the lubrication cycles are very long. Our NTN Automation application engineers will gladly help you to determine the maintenance intervals.

PDF Tech Tip: Click Here

Author: Jim Mangan