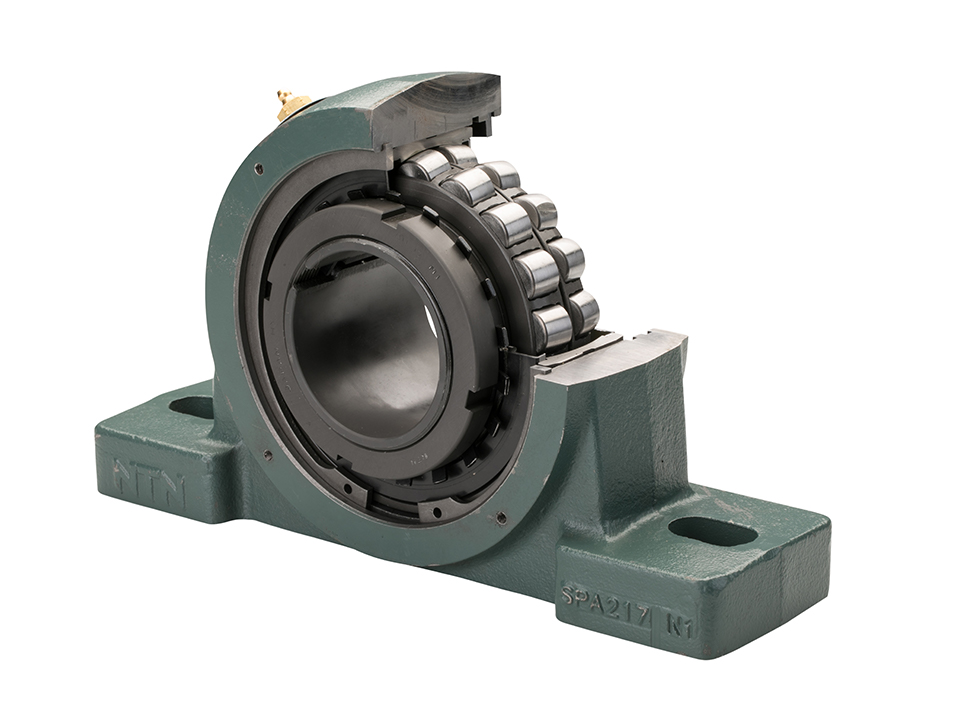

SPAW Heavy-Duty Bearing Units Can Accommodate Thermal Growth with Fixed and Floating Arrangements

Inherent to all bearing operation is heat generation originating from either internal friction within the bearing or from an external heat source. During operation, heat will transfer to the shaft and cause thermal growth in the axial direction. When selecting and installing bearings, the end-user must account for this shaft growth in the bearing arrangement to avoid additional, unwanted loading as this can lead to premature bearing failure.

General bearing practice dictates that the bearing on one end of the shaft should be “fixed” with respect to the housing for shaft rotating applications. This means that the bearing should be captured in the housing in the axial direction so as to avoid movement in the direction of the length of the shaft. This can be accomplished with housing shoulders and/or snap rings.

Additionally, the bearing on the opposite end of the shaft should “float” in the housing for shaft rotating applications. This bearing should not be constrained in the housing in the axial direction but rather free to move or “float” in the axial direction.

NTN’s SPAW/SPW/SFCW heavy-duty, one-piece mounted unit for demanding applications has a built-in feature for easy adjustment from a fixed to a floating arrangement. There are two snap ring grooves in the housing on one side of the bearing where the included snap ring can be positioned for either a fixed or floating arrangement. Place the snap ring in the groove closest to the bearing for the fixed position or place the snap ring in the groove farthest from the bearing for the floating position.

The setup of NTN’s SPAW/SPW/SFCW units is self-contained as the snap ring comes mounted in the housing. There is no need to order additional parts.

PDF Tech Tip: Click Here

Author: Mike Enes