NTN Starts Mass-production of “Low Dust Generation Bearing for Servo Motors”

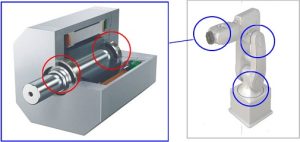

NTN Corporation (hereafter NTN) has begun mass production of the “Low Dust Generation Bearing for Servo Motors,” a bearing that significantly reduces dust generation and rotational torque for servo motors, which are widely used in industrial robots, machine tools, and semiconductor manufacturing equipment.

for industrial robots

Servo motors are equipped with rotation detectors (sensors/encoders) and brakes, enabling precision control of rotational speed and angle. As a result, they are used in industrial machinery that requires precise movements, such as industrial robots and machine tools. However, when dust particles such as oil components from the grease used in bearings adhere to the encoder, it can reduce detection accuracy. Similarly, if dust particles adhere to the brake disc, it may affect braking performance. Therefore, bearings for servo motors are required to suppress such particle generation.

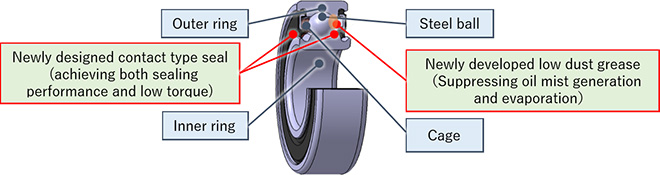

The “Low Dust Generation Bearing for Servo Motors” developed by NTN reduces dust generation by approximately 90% compared to conventional products by adopting a new low-dust grease developed through a review of its components and composition, and a newly designed seal with enhanced sealing performance. Furthermore, the seal maintains sealing performance while achieving approximately 50% lower torque compared to the conventional product by improving its shape.

In addition to enhancing the reliability of servo motor control through significant reduction of dust generation, the product has also been highly evaluated for its durability, allowing stable long-term use while maintaining low rotational torque. As a result, it has been adopted by a major motor manufacturer and has welcomed mass production.

Servo motors offer highly precise rotational control, and in recent years, their demand has been increasing, particularly in industrial robots and machine tools. Servo motors used in industrial and humanoid robots are often applied to drive joints, where downsizing and increased power output are required to increase shaft velocity and acceleration/deceleration velocity at joints. Since this product significantly suppresses dust generation from the bearing, it eliminates the need for sealing devices in servo motors, enabling a more compact design. Additionally, by maintaining low rotational torque, it also contributes to higher power output of servo motors.

NTN will continue to propose high-value-added products such as the “Deep Groove Ball Bearing for High Speed Servo Motors,” which is designed to support high-speed rotation and reduce vibration in servo motors for machine tools. Through these efforts, we aim to further contribute to the performance enhancement of servo motors.

Features (compared to the conventional product)

| 1. Low dust | Reduce dust generation by approximately 90% |

|---|---|

| 2. Low torque | Reduce rotational torque by approximately 50% |

Application

Servo motors for industrial robots, machine tools, semiconductor manufacturing equipment, etc.

ABOUT NTN

Founded in 1918, NTN is one of the world’s largest producers of premium quality ball and roller bearings, long recognized for the most stringent quality standards in the industry. With plants around the globe and a strong domestic manufacturing network, over 80% of the products sold by NTN in North America are made by one of the ten plants the company operates in the USA and Canada. NTN USA Corporation serves as the headquarters and holding company of NTN’s entities across the Americas, including its subsidiary companies for manufacturing and sales.