Preventing Raceway/Roller Damage During Installation

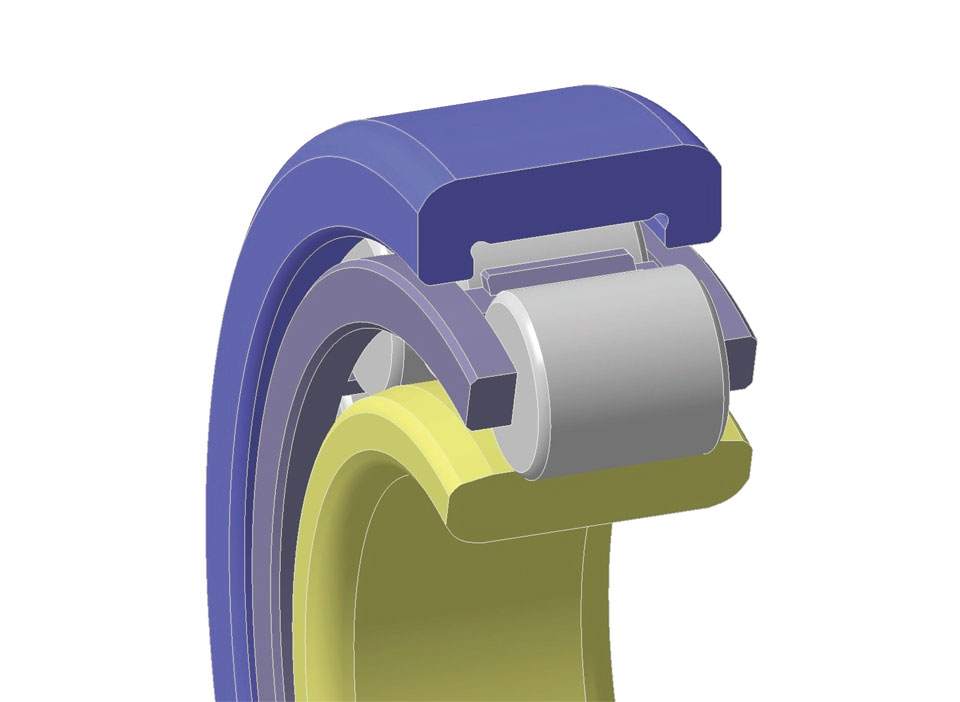

The NU and NJ type cylindrical roller bearings, as well as many machined ring needle roller bearings, facilitate mounting by removing the inner ring. In most instances, the inner ring must be press fitted to the shaft to prevent slippage during operation. By removing the inner ring and heating it, the inside diameter expands allowing the ring to be easily positioned on the shaft. With the outer ring and roller assembly mounted in the housing, the shaft/ inner ring can then be inserted under the rollers.

There are many different cage designs for these bearings but, in each case, the cage pocket must be of adequate width to allow the roller to turn without wear. When in a horizontal position, gravity causes the roller to “drop” in the pocket, making it difficult to properly align the shaft/inner ring to allow insertion. Any misalignment will cause scoring of the inner ring raceway and as well possibly damage the roller surfaces, also known as “plowing”.

To negate the effect of roller drop, in some cases the shaft can be inserted vertically and rotated as it is inserted to allow the rollers and raceway to properly align. It is also advisable to lubricate the rollers and raceway surface to aid in the insertion. If vertical assembly is not possible, again pre-lubricate the rollers and inner ring raceway and rotate the shaft/inner ring during the insertion allowing the rollers and raceway to align and prevent damage.

PDF Tech Tip: Click Here

Author: Roberto Carriedo