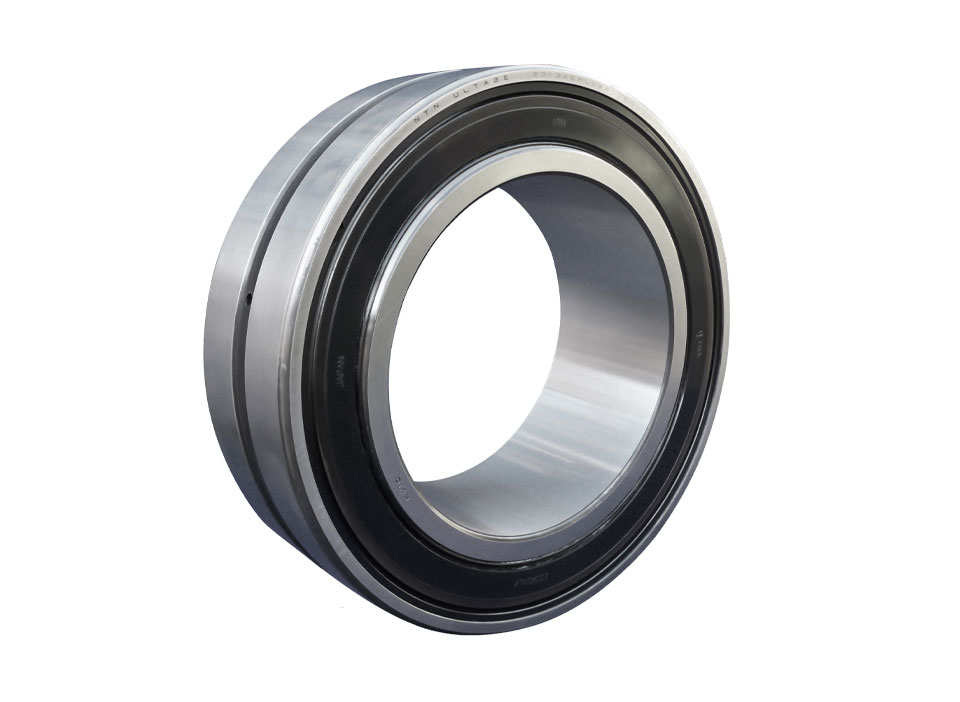

ULTAGE® Sealed Spherical Roller Bearings for Transport Conveyors

One of the harshest environments for bearings to operate in are transport conveyors that expose the bearings to heavy contamination that eventually migrates past the housing seals and into the bearing. This wreaks havoc on the bearing, making them run hotter and ultimately shortens the bearing life. In general these bearings are installed into tradition SAF split cast iron housings that are limited in good sealing options. One way the industry helped combat the ingress of contamination into the bearing is to develop sealed bearings, which incorporated the seal directly into the bearing. The issue with this design is it either reduces the capacity to stay within the ISO dimensions or the bearing becomes wider, thus requiring a special housing. Another issue is that the radial internal clearance cannot be measured during installation as the seals are fixed to the bearing.

NTN engineering has designed a removable seal for transport conveyor applications that maintains the highest capacity that we are known for in the ULTAGE design, while maintaining good sealing capability. The removable seal allows the installer to measure the radial internal clearance during installation to ensure the proper adjustment is made to maximize the life of the bearing. Also, by keeping the same ISO dimensions, these are a direct drop in for the traditional SAF designs.

PDF Tech Tip: Click Here

Author: Roberto Carriedo