What are the Benefits of the Machined Brass Cage in NTN’s Bower® Type E Mounted Bearing Units?

NTN’s Bower Type E mounted bearing units were created with your most demanding applications in mind. Whether it is misalignment, heavy loads, contamination, or excessive vibration, Bower Type E units can handle the toughest jobs.

The ability to withstand these grueling conditions is due in large part to the machined brass cage used in the Bower Type E. These cages are great for the following scenarios:

Heavy Loads:

• Machined cage with contoured cage pockets offers excellent stiffness and guarantees stability of the rolling elements, making it better suited for shock loading and applications with high vibration

High Heat:

• The “self-lubricating” properties of machined brass reduce heat generation, lessening the risk of cage seizure due to thermal expansion. Additionally, the lack of a floating guide ring or center shoulder allows for easier flow of lubrication, further reducing heat generation.

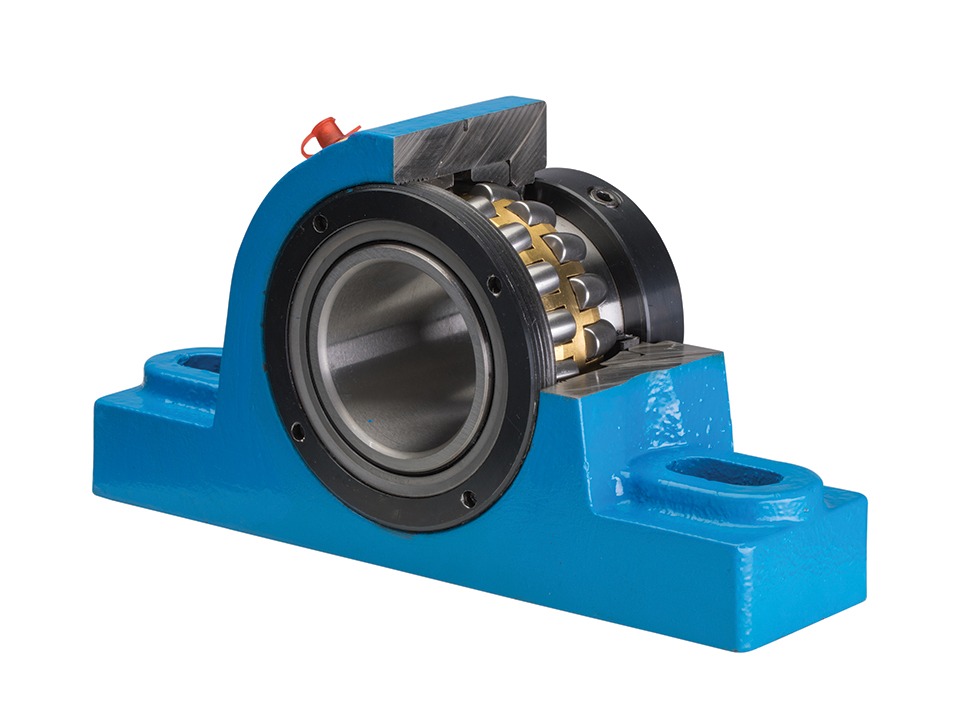

BOWER TYPE E BEARING UNITS

The Bower Type E with spherical roller bearing insert has what it takes to keep your equipment up and running. The bearing unit arrives fully assembled with grease and C3 bearing clearance. The spherical roller bearing insert allows for +/- 2° of misalignment to handle applications that may induce misalignment due to shaft deflection or uneven mounting surfaces. Bower Type E housings are made of cast iron with elongated bolt holes and are dimensionally interchangeable with competitive Type E bearing units.

• One-piece, sturdy cast iron housing to withstand demanding applications

• Threaded housing nut keeps the bearing clearance set and provides great seal support

• Self-aligning, double-row spherical roller bearing allows for easy alignment and can handle +/- 2° of misalignment

• Set screw locking collar secures the inner ring to the shaft

• Machined brass retainer with offset pockets results in cage stiffness for high vibratory applications

• Double-lip seal molded onto a metal guard provides superior sealing performance in extreme environments

• Elongated mounting slots for versatile mounting configurations

• Extended inner ring allows for greater contact surface to the shaft which provides better performance and stability

PDF Tech Tip: Click Here

Author: Roberto Carriedo