PRODUCTS

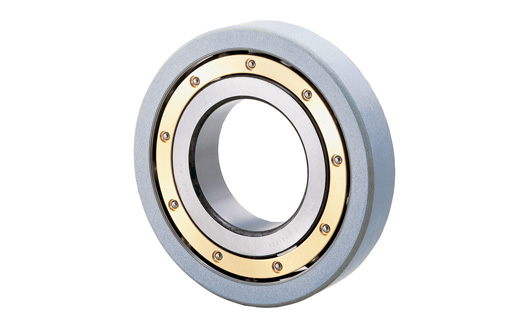

Ball Bearings

With more than ninety years of manufacturing expertise in ball bearings, NTN offers one of the industry’s widest arrays of products to fit your application. Our ball bearings are available to you off-the-shelf, in sizes ranging from 10 mm to 320 mm outside diameters. And with a virtually limitless variety of configurations of seals, shields, lubricants, internal clearances, and cage designs, there’s no reason to go anywhere else for your ball bearing needs.

Deep Groove Ball Bearings

Deep groove, or single row radial, ball bearings are the most widely used bearings in all general industries. They utilize an uninterrupted raceway that makes them optimal for radial loads. NTN radial ball bearings typically come with pressed steel cages, but also offer machined brass or molded nylon material. NTN also offers bearings with locating snap rings on the outside diameter.

PRE-LUBRICATED BEARINGS

Pre-lubricated bearings have integral seals, or shields, and are packed with long-life grease. In many applications, these bearings can be used without supplementary seals, closures, or protective devices.

Shielded ball bearings are protected on one or both sides by metal shields that are fastened to the outer ring. This close clearance shield retains the lubricant and helps prevent the entrance of large, foreign matter.

Sealed ball bearings incorporate steel-reinforced rubber seals that are securely fastened to a groove on the outer ring. Contact with the inner ring provides positive sealing at all times. We also offer a variety of contact, light-contact, and non-contact seals to help you to dial in your protection while balancing your speed and torque requirements.

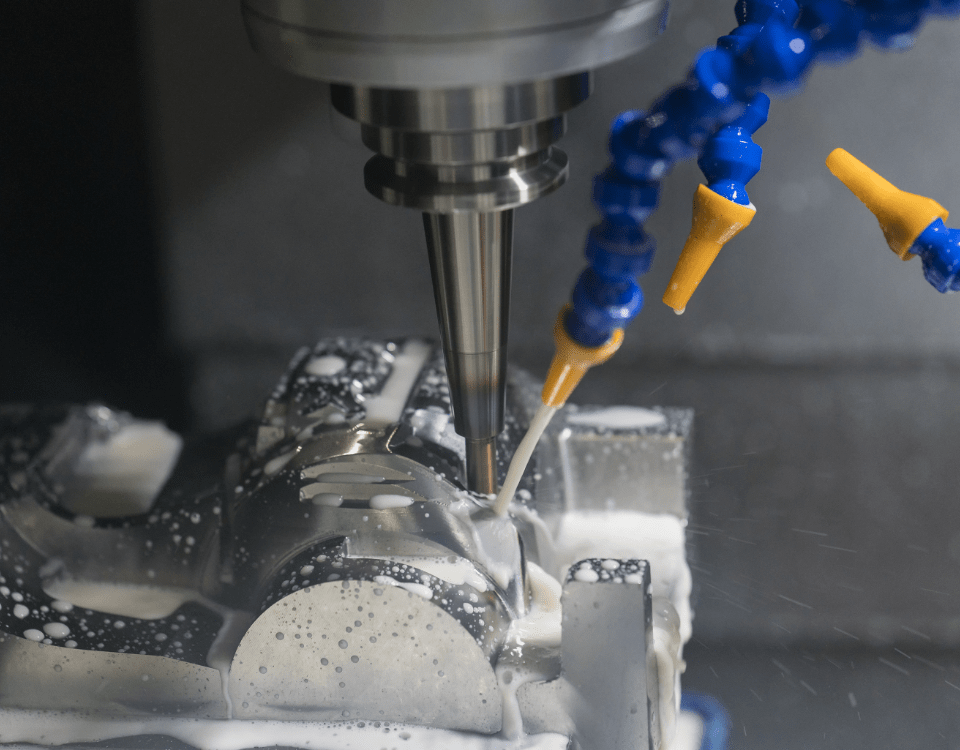

THERMAL MECHANICAL BALL BEARINGS (TMB): LIGHTER WEIGHT AND LONGER LIFE

With the heightened performance of today’s machinery, bearings are being used at higher loads and speeds. As a result, the industries using this machinery demand bearings with longer-lasting, compact designs, at lighter weights and lower costs. When manufacturing these bearings, stringent industry requirements must be met without changing the configuration of the related parts.

At NTN, we’ve met these challenges by manufacturing the Thermal Mechanical Ball Bearing (TMB). NTN TMB Bearings feature:

- Clean, vacuum-degassed, high-carbon chromium steel that undergoes a proprietary heat treatment to reduce crack sensitivity.

- High-power density that allows a smaller bearing to support higher loads.

- A wide range of sizes.

NTN TMB Bearings are available with all the features of a standard bearing—seals, shields, and clearances—so be sure to ask for them when looking for replacement parts.

Angular Contact Ball Bearings

SINGLE ROW ANGULAR CONTACT

Single row angular contact ball bearings feature raceways with high and low shoulders. These opposing raceways are designed to carry thrust load in one direction. NTN can preload the bearings at the factory so that the correct load will develop once the bearing is put into service. The bearings in this series are assembled with a specific internal clearance, so that they will have a specified contact angle under load. The standard contact angle used by NTN is 30° but, in many cases, a 40° contact angle can also be specified. We also offer special high-speed bearings with phenolic resin cages and a 15° contact angle.

DOUBLE ROW ANGULAR CONTACT

Double row angular contact ball bearings have an inner and outer ring with a double raceway. The two rows are oriented so the contact angle is similar to a pair of back-to-back single row bearings. NTN’s 5200 and 5300 series offer a one piece inner ring double row raceway that can carry thrust loads in either direction. The 3200 and 3300 series have filling slots, so it is necessary to mount them with the thrust load acting against the un-notched face of the rings.

Insulated Ball Bearings

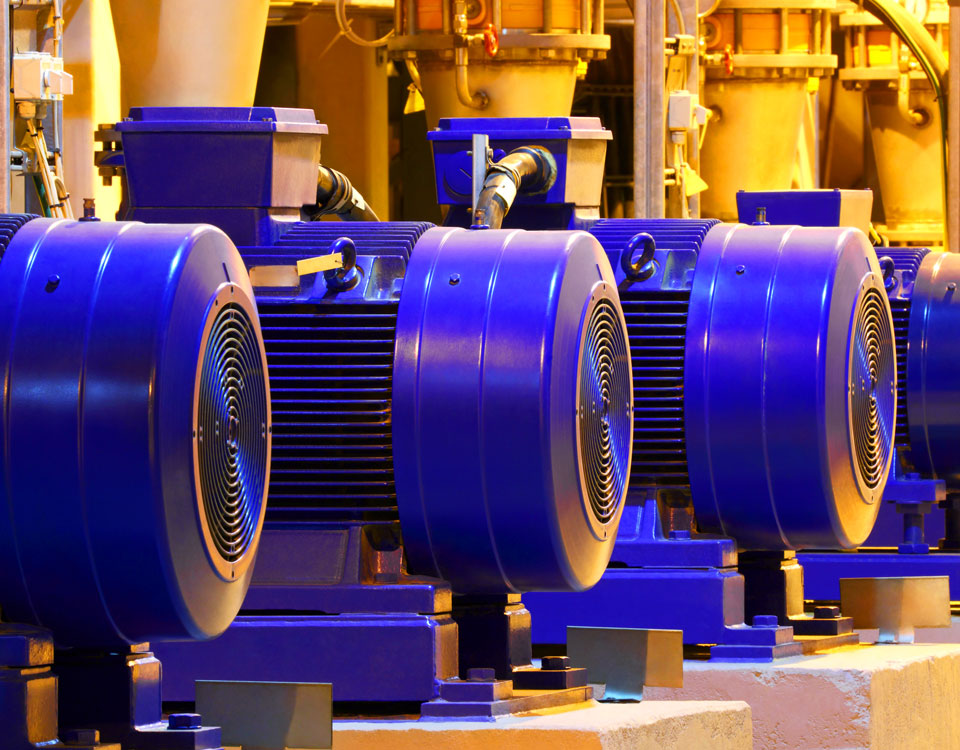

Electrical pitting often occurs in bearings used in electrical equipment, such as motors and power generators, as a result of current leakage. An electrical current present near a bearing can flow through the bearing, causing the current to arc between the rolling elements and the rolling surface. The arc created will elevate the temperature of the steel at the arc point and change the material structure of the steel, ultimately leading to bearing failure. This electrical pitting can be prevented with coated bearings or ceramic hybrid bearings.

COATED BEARINGS

NTN’s MEGAOHM™ Series of insulated bearings has been specifically designed to counteract electrical pitting. These bearings are available in both ceramic and resin versions that are suited to a variety of applications. Coating the outer ring of the bearing provides a barrier (capable of resisting at least 100 Megaohms and up to 2000 Megaohms at 500 VDC) against any stray currents that would pass through the bearing.

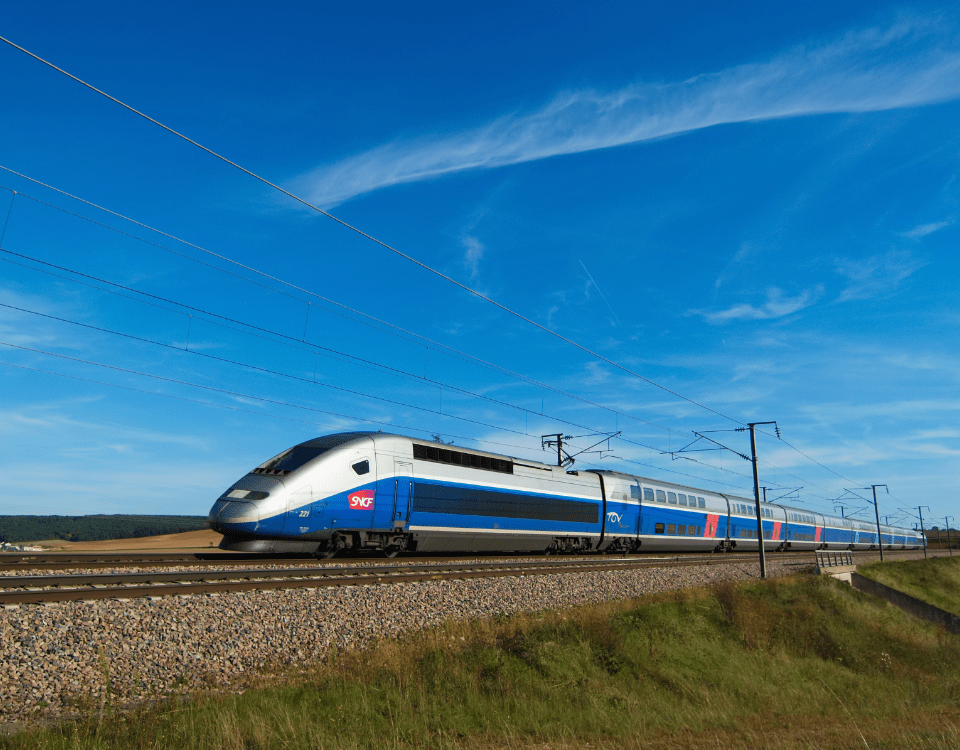

MEGAOHM™ Series bearings are featured as OEM equipment on wind turbine generators, traction motors for railway cars and variable speed electric motors in wastewater treatment facilities.

NTN’s MEGAOHM™ Series of bearings is engineered specifically to handle the demands of electric motor applications; click here to learn more.

CERAMIC HYBRID BEARINGS

For especially problematic applications, NTN offers ceramic hybrid bearings. Using conventional steel inner and outer rings, silicon nitride rolling elements provide excellent electrical insulation while reducing rotating mass and improving heat dissipation.

The unique properties of ceramic rolling elements can also extend service life and extend grease intervals.

Ceramic hybrid bearings are gaining popularity in the wind energy industry, where service access is difficult and conditions especially harsh.

Speciality Ball Bearings

Double-row, self-aligning bearings utilize an inner ring with a single spherical raceway. In this configuration, the inner and outer rings can be misaligned relative to each other. The boundary dimensions of self-aligning bearings can be the same as standard ball bearings.

FOCUS ON RELATED APPLICATIONS

NTN products are critical to keep the world moving smoothly. Our bearings and related products are present in a wide variety of industries. Please see the industries below that have applications for this product category.

DELIVERING NTN

SOLUTIONS

AUTHORIZED DISTRIBUTOR SEARCH

NTN has dozens of manufacturing plants and distribution centers throughout the Americas, to keep our distribution channels fully stocked. Use our distributor locator tool to find a distributor close to you.

BEARING FINDER

Are you looking for a specific size of bearing? Do you have an NTN or other part number to look up? Do you need a CAD file or technical specifications? Find and download the bearing information you need with NTN’s robust online product catalog tool.

CONTACT US